Going Bravely Ahead

By Zach Fothergill

At UCEC, we always seek ways to do things better and be more efficient. From sending Garrod and Ron to Underwriters Laboratory to learn the latest safety testing standards for hazardous locations, to staying in touch with new tech at tradeshows, we know that embracing the future of manufacturing is vital. If you don’t, more so than ever, it’s going to blow past you.

I think for about 30-40 years, manufacturing didn’t change too much. But now, there are so many electronics involved with manufacturing including apps and robotics, not to mention the Internet of Things (IoT). A lot of panel shops haven’t changed much, but not UCEC.

Earlier in May, Garrod and John Beattie went to the Electric Wiring Processing Technology Expo in Milwaukee, WI. Our actual day-to-day work, which is all about automating things, is interestingly unautomated. So, Garrod and John checked out technology that helps craftsmen like us do things more efficiently.

In September, Morgan Burriss and I will travel to Chicago for the International Manufacturing Technology Show. As luck would have it, we stumbled on this show two years ago when we were in town for something different. It’s a worldwide show that occurs every two years. People fly in and bring huge machines the size of small houses and set them up. We have our eyes on some really great technology, so hopefully, I can report back in the fall about that.

I think the best part about seeing new tech hit the shop floor is how it makes us better. We build panels so much faster than we did when I started nearly ten years ago. The quality is better and we make many, many more panels. We’re made our work efficient, and that’s due to a number of factors, but technology is a large part.

Zach is an Operations Support Manager at UCEC.

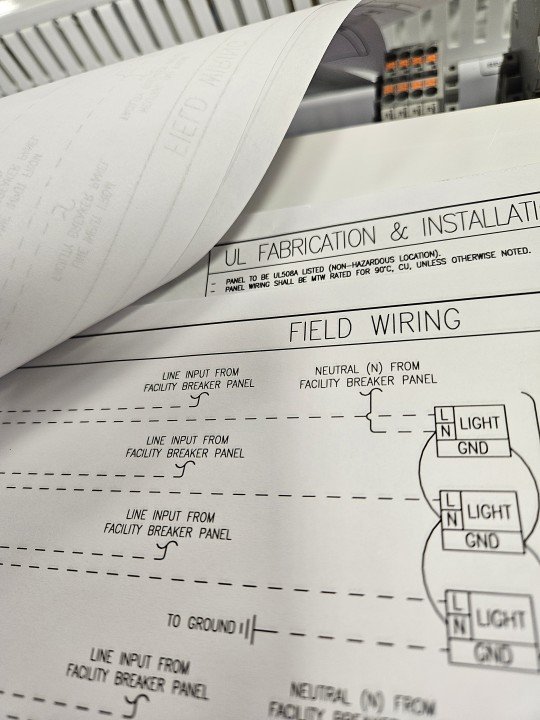

UL Certification is critical across multiple sectors, including: Oil & Gas, Chemical Manufacturing, Mining, Pharmaceuticals and Food Processing. Industries where explosive atmospheres are common must prioritize UL Certification to maintain safety and compliance.