We publish stories about our unique shop environment, our talented craftsmen and our dedication to our customers, and whatever else is on our minds.

In the ever-evolving landscape of industrial automation and energy management, the pursuit of energy efficiency remains a central focus for organizations worldwide. As industries strive to optimize resource utilization, reduce operational costs, and minimize environmental impact, the design and implementation of energy-efficient control panels have become increasingly critical.

In the dynamic landscape of industrial operations, the quest for energy efficiency has emerged as a cornerstone of sustainable business practices. As industries seek innovative solutions to minimize energy consumption and reduce environmental impact, the integration of energy-efficient control panels has become increasingly prevalent. In this article, we explore real-life examples of energy-efficient industrial control panels and their transformative impact across diverse applications and industries.

In the dynamic landscape of industrial operations, the optimization of energy consumption within control panels stands as a critical imperative for enhancing operational efficiency, reducing costs, and minimizing environmental impact. As industries strive to achieve sustainability goals and improve resource utilization, the process of optimizing energy consumption in industrial control panels emerges as a strategic priority.

In the dynamic landscape of industrial operations, the efficient management of power within control panels stands as a cornerstone of optimal performance and sustainability. As industries strive to minimize energy consumption and enhance operational efficiency, the implementation of effective power management techniques has emerged as a critical imperative. In this article, we explore the key strategies and methodologies involved in power management for industrial control panels, including the implementation of efficient power distribution systems, utilization of smart control algorithms, and incorporation of energy monitoring and feedback mechanisms.

In the realm of industrial control panel design, the selection of components plays a pivotal role in shaping not only the functionality and reliability of the system but also its energy efficiency. As industries increasingly prioritize sustainability and operational cost-effectiveness, the careful consideration of energy-efficient components has become paramount. In this article, we explore the key principles and strategies involved in selecting energy-efficient components for industrial control panels, ranging from choosing components with low power consumption to integrating cutting-edge technologies for energy savings.

Industrial control panels stand as the backbone of modern manufacturing and operational processes, serving as the nerve center that orchestrates complex systems with precision and reliability. Across diverse industries ranging from automotive manufacturing to power generation, these panels play a pivotal role in ensuring seamless operations and optimal performance.

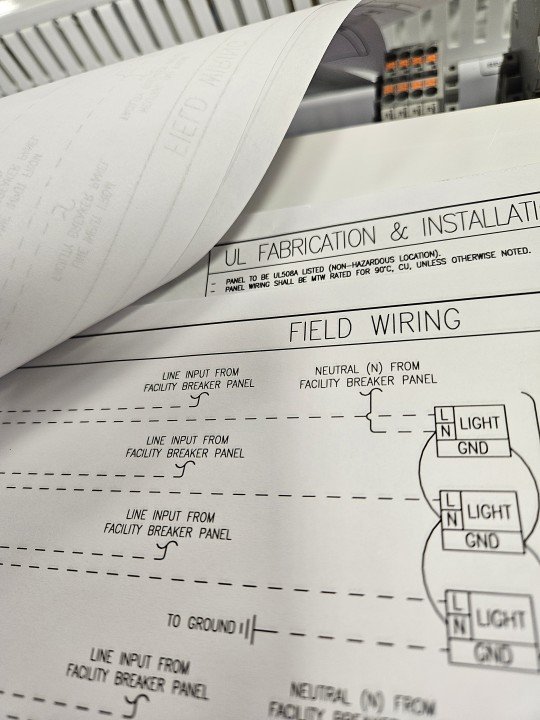

While both schematic drawings and wiring diagrams are types of technical drawings used in electrical engineering, they serve different purposes and present information in distinct ways. Here are the key differences between schematic drawings and wiring diagrams.

The true cost of ownership of an industrial control panel goes beyond the initial purchase price. Several factors contribute to the overall cost of ownership.

CATEGORIES

Keep up with UCEC

Sign up for our blog posts, below. We’ll make sure to send each new story to your inbox.

In today's industrial landscape, control panels serve as vital components across various industries, orchestrating complex systems with precision. Recognizing the significance of energy efficiency in control panel design is paramount for reducing costs and minimizing environmental impact. Let's explore the key points and a compelling call to action for embracing sustainable practices in engineering and design.